| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 90 Days |

Model No.: Yz71

The four-column hydraulic Machine body adopts 45# integral cast steel, which is tempered and tempered by tempering. It is a three-beam four-column structure, simple, economical and practical. The frame design has high rigidity and high precision through finite element analysis. It is the shipbuilding industry. The automotive industry, the preferred products for the pressure vessel industry, chemical industry, etc., the hydraulic press for professional Manhole Covers.

Furthermore, you can benefit from the ZHENGXI know-how in complete automated production lines, all our presses can be implemented with automatic loading and unloading robots, cutting systems or other add-on equipment such as HP RTM or vacuum systems, GMT oven or thermal regulation skid. ZHENGXI press systems can run both automatically and semi-automatically, whatever your needs. More than 100 units are running worldwide, manufacturing parts for well-known companies of the auto, aeronautics, aerospace and energy industries.

Hihghlights

ZHENGXI is dedicated to serve the industry by providing innovative solutions to the most demanding needs of our customers. That is why we are proud of our custom engineered machine solutions which combine excellence with an environmentally-friendly approach. The ECS PRESS, our new state-of-the-art short stroke press, is the last evidence of our commitment.

Features

1. Computer optimized frame structure, tempered after vibration aging, good rigidity and high precision

2. Integrated cartridge valve system, less leakage point, small impact, reliable action, beautiful appearance and long service life

3. Wear-resistant pressure-resistant polyurethane new cylinder sealing components (Taiwan) fast, reliable, long life

4. The column guide rail is provided with lubrication device

5. Complete safety device, cylinder lower chamber support circuit, cylinder upper and lower chamber interlock circuit, overflow valve pressure regulation and electric contact high pressure limit double adjustment, upper and lower limit position sensor, superior safety

6. The electrical system is controlled by relay or P L C. The electrical capacity is large and the reliability is high.

7. It can realize two forming processes of constant pressure and fixed stroke, with the function of holding pressure delay and adjustable delay time. The working pressure and stroke can be adjusted according to the process requirements within the specified range, and the operation is simple.

Parameters

| Mold | unit | 63T | 100T | 160T | 200T | 250T | 315T | 500T | 630T | 800T | 1000T | 1250T | 1500T | |

| Main cylinder (slider) process specs | Max.press force | KN | 630 | 1000 | 1600 | 2000 | 2500 | 3150 | 5000 | 6300 | 8000 | 10000 | 12500 | 30000 |

| Max.return force | KN | 150 | 100 | 315 | 450 | 540 | 630 | 1000 | 1000 | 1200 | 1600 | 2100 | 2500 | |

| Down speed | mm/s | 100 | 100 | 160 | 160 | 140 | 140 | 140 | 250 | 200 | 150 | 150 | 140 | |

| Slow speed | mm/s | 20 | 15 | 15 | 15 | 12 | 15 | 15 | 15 | 15 | 15 | 12 | 15 | |

| The proportion of floating pressing speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | |

| Press speed | mm/s | 10 | 10 | 10 | 10 | 7 | 8 | 8 | 8 | 8 | 8 | 6 | 8 | |

| Return speed | mm/s | 120 | 120 | 120 | 110 | 95 | 100 | 100 | 150 | 150 | 120 | 120 | 120 | |

| Max.stroke | mm | 400 | 500 | 500 | 500 | 500 | 500 | 600 | 600 | 600 | 600 | 600 | 600 | |

| Top cylinder process specs | Max.ejection force | KN | 280 | 440 | 450 | 900 | 900 | 1250 | 1800 | 2200 | 2200 | 2750 | 2750 | 10000 |

| Max.pull force | KN | 280 | 360 | 450 | 750 | 750 | 1250 | 1800 | 2200 | 2200 | 2750 | 2750 | 3150 | |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Eject speed | mm/s | 80 | 34 | 65 | 55 | 50 | 50 | 50 | 60 | 60 | 60 | 60 | 60 | |

| Floating speed | mm/s | 20.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | 15.00 | |

| Return speed | mm/s | 80 | 42 | 95 | 70 | 70 | 50 | 50 | 60 | 60 | 60 | 60 | 60 | |

| Upper center cylinder process specs | Max.press force | KN | 60 | 60 | 60 | 125 | 150 | 125 | 200 | 200 | 240 | 240 | 300 | 500 |

| Max.return force | KN | 30 | 30 | 30 | 76 | 76 | 76 | 130 | 130 | 140 | 140 | 200 | 260 | |

| Max.stroke | mm | 30 | 30 | 30 | 45 | 45 | 45 | 50 | 50 | 50 | 50 | 50 | 50 | |

| Under center cylinder process specs | Max.press force | KN | 70 | 70 | 125 | 160 | 160 | 200 | 200 | 300 | 300 | 300 | 400 | 1000 |

| Max.return force | KN | 40 | 40 | 75 | 100 | 100 | 100 | 100 | 200 | 200 | 200 | 260 | 315 | |

| Max.stroke | mm | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Upper floating cylinder process | Max.press force | KN | 120 | 120 | 130 | 250 | 250 | 300 | 400 | 400 | 480 | 480 | 500 | 1000 |

| Max.return force | KN | 60 | 60 | 65 | 150 | 150 | 160 | 200 | 200 | 240 | 240 | 250 | 250 | |

| Max.stroke | mm | 45 | 45 | 50 | 60 | 60 | 70 | 70 | 70 | 70 | 70 | 70 | 70 | |

| Effective worktable size | L-R | mm | 580 | 720 | 780 | 1000 | 1000 | 1000 | 1200 | 1320 | 1400 | 1600 | 1760 | 2400 |

| F-B | mm | 490 | 580 | 640 | 940 | 940 | 960 | 1140 | 1200 | 1200 | 1350 | 1460 | 1500 | |

| Max.pressure of liquid | mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Max.filling height | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | |

| Main motor power | KW | 7.5 | 11.5 | 18.5 | 22 | 22 | 30 | 48 | 67 | 82 | 100 | 100 | 127 | |

Application

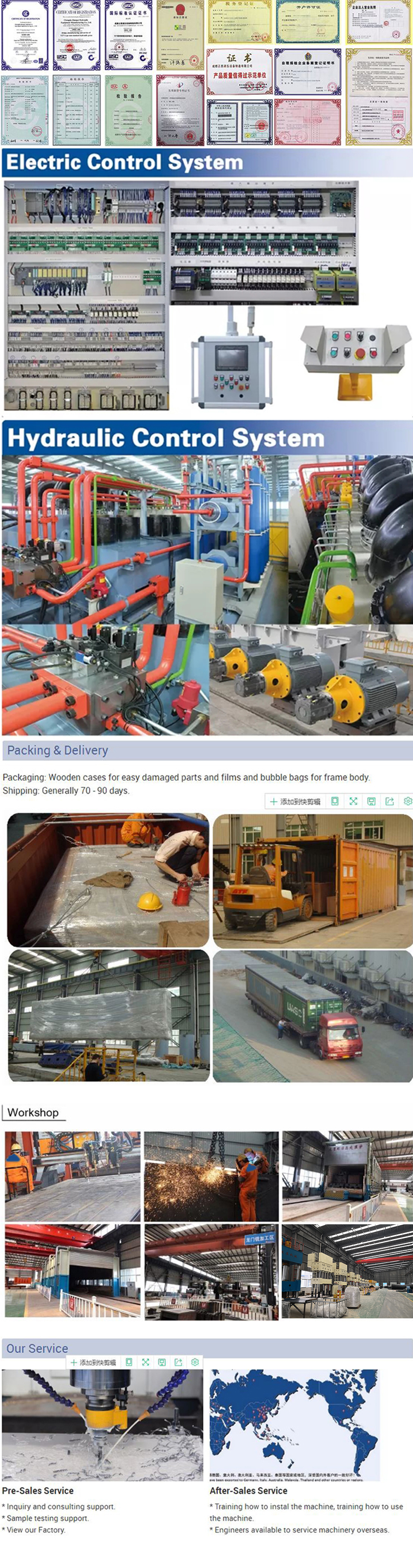

Certificate

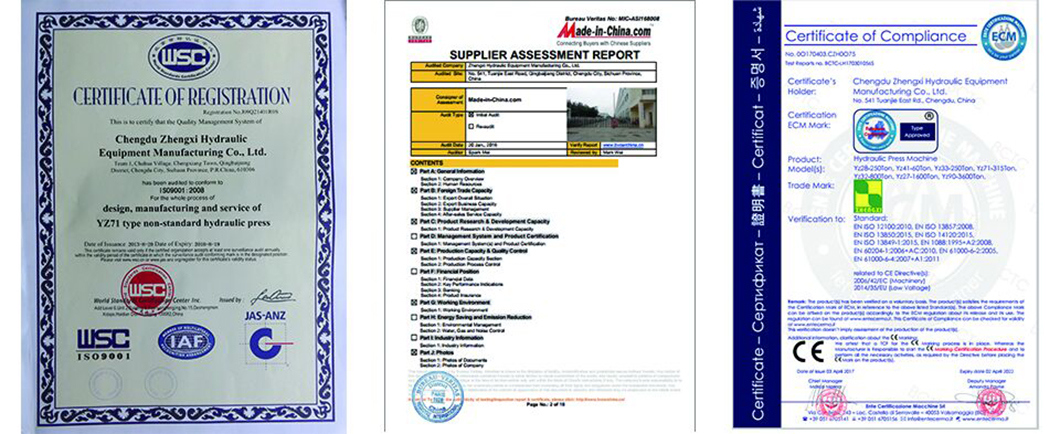

Packaging and delivery

Certificate

Contact info

After-sale

1.Personnel training

Free training for about one week.

2. After-sale service

One year warranty.During warranty period,free maintenance service can be provided.(except man-made faults or damages arising from irresistible natural factors)

3.Installation

Customers need to pay the commission to our proffessional engineer, and travel expense is on foreign customer.(Including round ticket and accommodation cost)

Our company is an ISO 9001 certified Company, and as an approved supplier for the automotive sector, has also received the CE certificates.This demonstrates that the Quality Assurance System has been fully introduced and adopted, in the interests of providing absolute reliability in our products and careful attention to our customers.

FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in all kinds of machines ,such as 1-16000Tons Hydraulic Press,SMC/BMC/GMT/DMC/LFT/GRP/FRP Press,Hydraulic Deep Drawing Press,Hydraulic Forging Press,Metalworking/Stamping Press.

3: Where is our factory located? How can I visit there?

A : Our factory is located in Jiaomei City ,Fujian Province,China. You are warmly welcomed to visit us.

4: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

5: How about your delivery time?

A: Generally 90 days. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

6: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

7: How do you make our business long-term and good relationship?

A: 1.We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Product Categories : SMC-BMC-GMT > Others SMC-BMC-GMT